Took a break from sanding this weekend and decided to try to make some 550-style clam latches.

Got pretty far along in the 9 or so hours I spent working from the junk pile. Why do this?

Three reasons:

- It’s cool. Original Spyders had these latches you turned with a long churchkey; the replicas don’t. More legit-looking detail is just better.

- The modern replicas use two Bug hood latches to hold the clam down—and they’re fiddly. It is reported that clams sometimes pop open on bumps, leaving just the wicked-cool leather straps to keep the clam from flying up and off and causing quite a ruckus out there on Highway 61. Adding a slot-lock as original can only make things better, from a purely practical perspective.

- I’m tired of sanding.

Here are some spectacular close-ups of the thing we’re copying, as stolen from Type550.com:

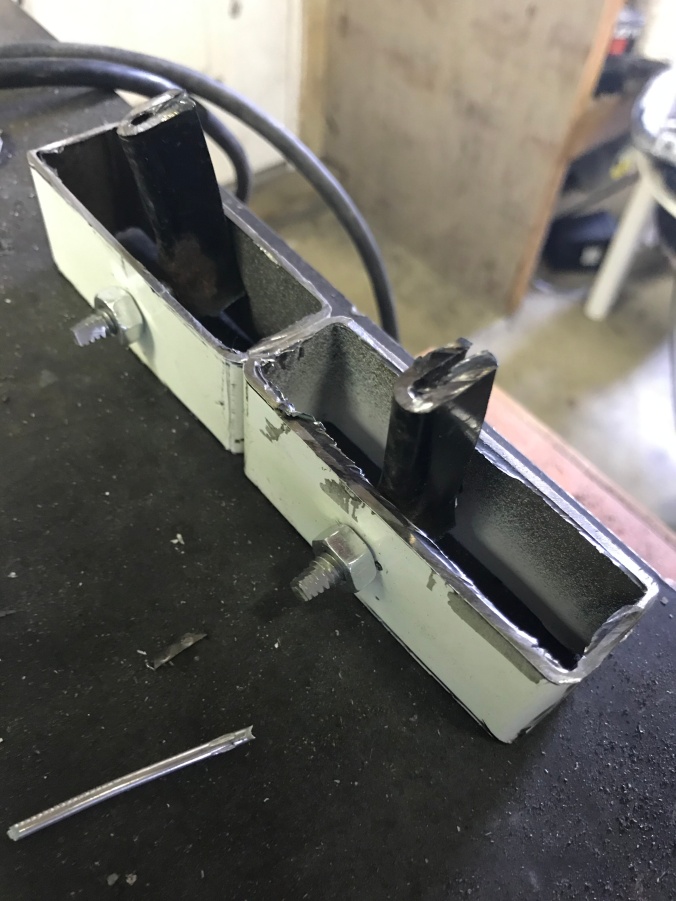

The slot for the locking bolt is just above the top bolt for the bottom latch, in a steel plate that fronts a box, inside of which the works live. Here’s the box:

So, just a matter of making a couple of L-shaped plates, drilling a hole through them, rigging up some kind of swing arm, welding the plates to a front plate, and riveting it all in place.

As always, I started with CAD.

My biggest concern was lining up the pivot with the latch cover hole, since both covers have already been dry fitted. I found there’s a bit of wiggle room there.

The remnants of a treadmill offered up a pretty good housing for the mechanism. The lower valance from a discarded dishwasher made the front plates.

The remnants of a treadmill offered up a pretty good housing for the mechanism. The lower valance from a discarded dishwasher made the front plates.

I filed a bit of 1/4-20 all-thread to work with the little key that came with my front latches.

An old battery hold-down has the right shape to make a strong lever arm or bolt.

Now to test-fit….

Ahh, but before I can do that I have to make the church key.

So this is all just snapped together for now. I’ll braze it up later.

So this is all just snapped together for now. I’ll braze it up later.

I held the box in place and found the squared all thread with the churchkey. It’s a bit fiddly to work the tool down in the hole and hit the right spot, but nothing a little practice won’t make routine.

I tacked the nuts to the box, welded the levers to the all thread and then tacked the box to the driver’s side plate.

And that’s about all the time we have.

Over the week I’ll finish the other male latch and then Cad up the female side. It will be tricky fitting the catches in because there’s no way to see them even from underneath and inside—the design of the replica blocks access.

But I think I’ve worked out a method to make it all fit tight.